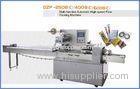

Auto PVC / PTPP Blister Packing Machine , Tea Bag / Cookies Packaging Equipment

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Auto PVC / PTPP Blister Packing Machine , Tea Bag / Cookies Packagin

Auto PVC / PTPP Blister Packing Machine , Tea Bag / Cookies Packaging Equipment

Quick Detail:

|

Type |

Blister Packing Machine |

|

Applications |

|

|

Packaging Material |

PVC PTP PVDC |

|

Certificate |

CE ISO 9001 GMP |

|

After service |

Engineers available to service machinery overseas |

|

Packaging detail |

Plywood case is the usual exporting packing , also can packing according to the customer's requirements |

|

Delivery Time |

30 days after got Your down payment |

Description:

DPR-250B Tropical (ALU-PVC-ALU) Blister Packaging Machine is the innovation product in China and got two patents of the state (patent NO:ZL01239101.8 and ZL01239100.X). It can be used for three packing kinds for ALU/PVC, ALU/ALU, ALU/PVC/AVC and up to the purpose that a machine with three usages just to change moulds.

Feature:

1. Mechanical drive: adopts the most new-type high-power transmission chain to drive the main drive shaft, avoiding the errors and noises when the gear wheel under transmission.

2. Electric apparatus system: adopts German Siemens PLC controlling system or Japan Omron PLC controlling system, resulting each station transmission is programmable.

3. Detection system: according to customers’ requirement, it adopts camera detector which can distinguish 5% different shape of pharmaceutical sample and delete it automatically. Or it adopts the optic fibre detecting & eliminating system that can count and reject empty blister pack.

4. Pneumatic system: adopts coder control and programs with PLC that make each operating station accurate. It guarantees the stability of moving ahead simultaneously when packing products operating in many stations and long distances.

5. Servo traction system: Adopting double servo equipments, Panasonic servo-motor traction device to control, in order to keep the stability of moving ahead simultaneously while each apparatus are in high speed and long-distance working.

6. Photoelectric registration for printing equipment: using servo motor to control traction system, and photoelectric switch to detect the length, thus makes print pictures and texts to be clear and pleased, and improve the level of the products packing.

7. Split combined type body: It is convenient to enter the purification workshop and fitted up smoothly for the user. And it’s easy to install and convey.

8. All the parts is made of stainless steel (316 or 304) and prevent the across infect which completely meets the "GMP" standard.

9. This machine can be equipped with safety cover, and automatically finish forming, feeding, hot-sealing, tropic alu forming, second hot-sealing, perforating, and trimming.

Specification:

|

Productivity: |

40,000-80,000 Pieces/hour |

|

Travel adjusting range: |

40-130 mm |

|

Cutting frequency: |

15-40(Frequency Conversion Adjustable)Time/min |

|

Max.of forming area and depth of PVC: |

240×120×18 mm |

|

Max.of tropic Alum,-plastic: |

220×110×20 mm |

|

Heating plate Power: |

1.5(upper)KW 1.5(lower)KW |

|

Hot-sealing power of Alum,-Plastic: |

3KW |

|

Hot-sealing power of tropic Aluminum: |

7KW |

|

Power of main motor: |

2.2KW |

|

capacity of air compressor: |

≥0.2m3/min |

|

Size of wrapper(width): |

PVC/AL Foil,Tropical Al 250mm |

|

Weight: |

2500Kg |

|

Overall size: |

4750×1200×1800mm |

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

RuianHaichina Machinery Company [China (Mainland)]

Business Type:Manufacturer

City: Wenzhou

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español